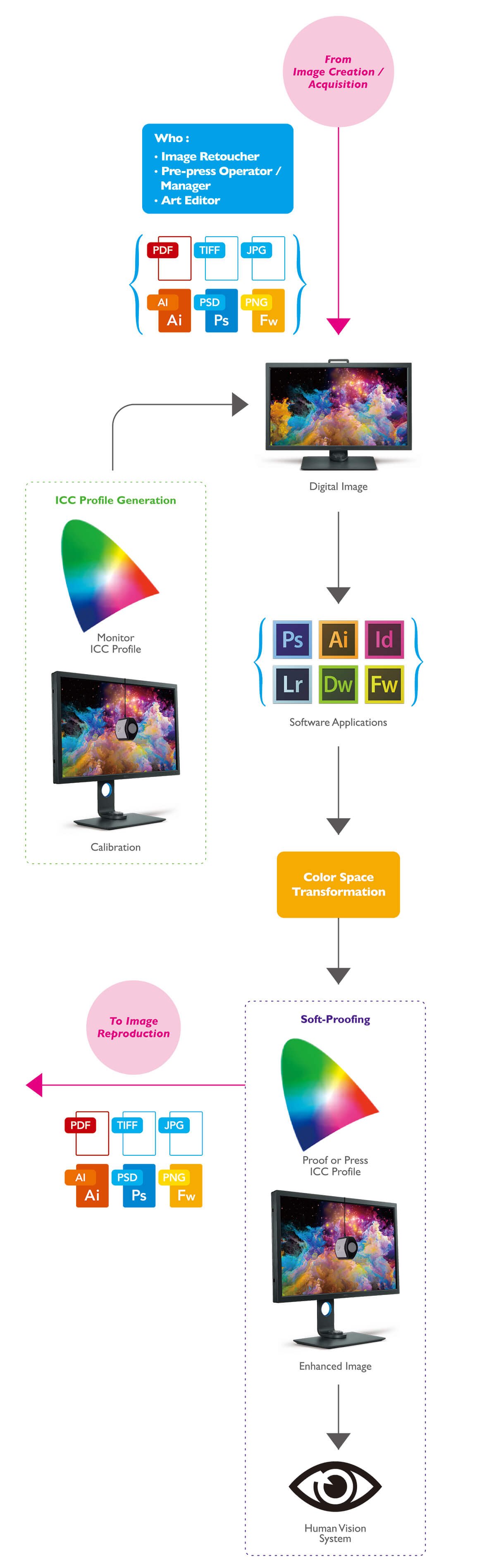

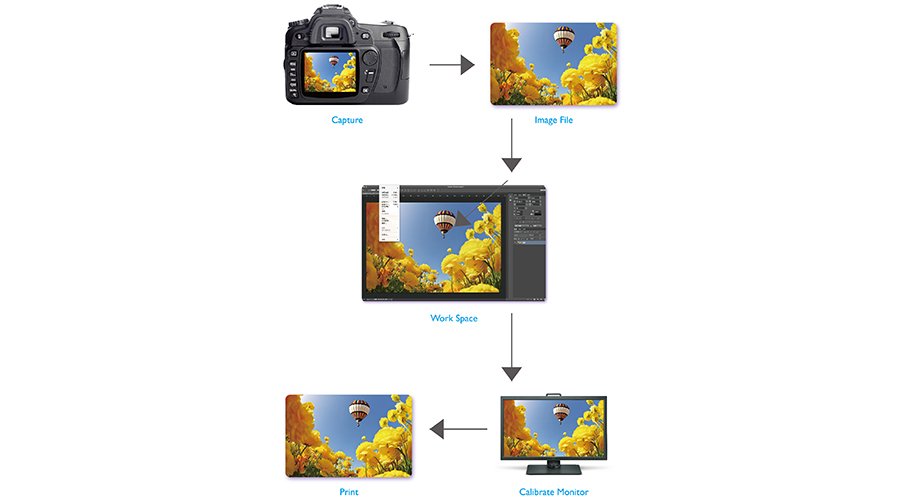

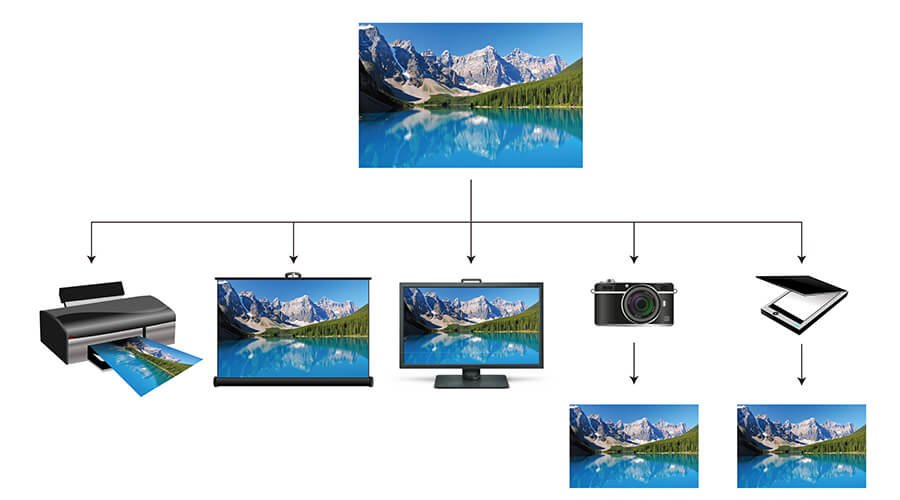

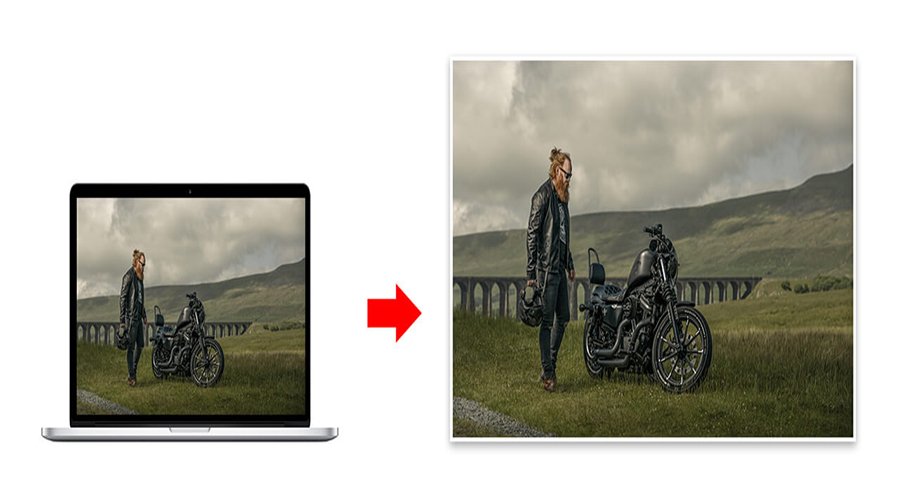

As you may notice in the workflow, there is a block called “Soft-Proofing”. This is a unique function offered by color management workflow, and it can be considered the most important and powerful function in the workflow. Soft-proofing is the ability of the user to actually preview the printed image before it is printed. The user, in this case a retoucher or a pre-press operator, can review the image from the monitor and see what it will look like when printed on paper. The monitor acts as a “simulator”. With the help of a printer ICC profile and a properly calibrated monitor, a retoucher can have an accurate approximation of what the image will look like if printed on glossy paper or matte paper. He or she could make the right adjustments to the image to have the best output on the printed substrate. The benefit of soft-proofing are the savings of tons of time and consumables (paper and ink). In the past, the proofing was done by reviewing the printed hardcopies. The printers had to send different versions of printed images to their customers, and wait for customers to send their comments back on the printed images. This process was repeated until the final image met the requirements of the customers. This was a very expensive and time consuming process. But now this can be replaced by a soft-proofing process. All the images and comments can be sent electronically to avoid delay in time and expenses for consumables and delivery. The best part is that all you need to implement a soft-proofing process is to have a good, properly calibrated monitor, the ICC profile for the output printer, paper and ink set, and the software to carry out the color transformation, such as Adobe Photoshop and Acrobat.